- Home Page

- Company Profile

-

Our Products

- Industrial Chillers

- Blow Moulding Chiller

- Water Cooled Chillers

- Acid Chillers

- Injection Moulding Chiller

- Beverage Chillers (Juice Chillers)

- Chiller for Extrusion Lines

- Chiller For Anodizing

- Anodising Chiller

- Chiller For Anodising

- Co2 Gas Chillers

- Ammonia Milk Chillers

- Bio Gas Chillers

- Bottling Plant Chillers

- Industrial Process Chillers

- Low Temperature Chillers

- Chiller For Electroplating

- Batching Plant Chiller

- Air Chiller

- Air Cooled Scroll Chiller (Single Compressor)

- Chilling Plant Turnkey Project

- Blown Film Plant Chillers

- Industrial Scroll Chillers

- Semi Hermetic Chiller

- Laminating Chillers

- Screw Chillers

- Scroll Water Chiller

- Cooling Tower

- Chilling Plants

- Oil Chillers

- Scroll Chiller

- Glycol Chillers

- Chillers

- Screw Type Water Chiller

- Air Cooled Chillers

- Industrial Chillers

- Extra Links

- Contact Us

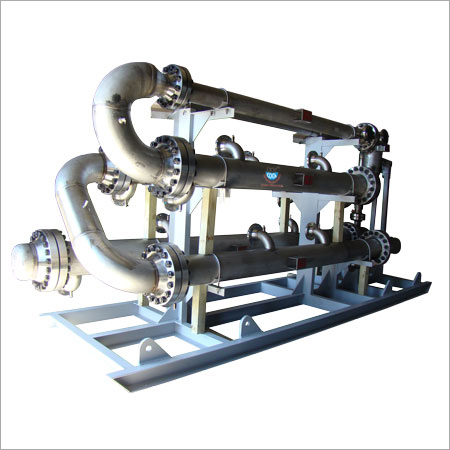

Laminating Chillers

100000.00 - 1000000.00 INR/Piece

Product Details:

X

Laminating Chillers Price And Quantity

- 1 Piece

- 100000.00 - 1000000.00 INR/Piece

Laminating Chillers Trade Information

- 5 Piece Per Month

- 15 Days

- South America Middle East Africa Western Europe Australia Central America Eastern Europe Asia North America

- All India

Product Description

Laminating is a process used in a variety of industries, such as paper and plastic production, to bond layers of material together using heat and pressure. A laminating chiller is a type of industrial chiller that is used to cool the rollers and other components used in this process. The chiller works by circulating chilled water or a refrigerant through the laminating machine, which helps to remove excess heat generated during the lamination process. This is important for maintaining the quality and consistency of the finished product, as well as increasing production efficiency by allowing for faster cycle times.

Laminating chillers are typically designed to handle high heat loads and operate at low temperatures, typically between 20-25 degrees Celsius (68-77 degrees Fahrenheit). They may use air-cooled or water-cooled condensers, and may be equipped with a range of features such as digital temperature control, automatic water level control, and remote monitoring capabilities.

Choosing the right laminating chiller will depend on a variety of factors, including the size and complexity of the laminating machine, the specific cooling requirements of the process, and the type and thickness of materials being laminated. It is important to work with a knowledgeable supplier or manufacturer to select and install the right chiller for your specific needs.

FAQ

1. What is a laminating chiller?

Ans - A laminating chiller is a machine used to cool hot surfaces during the laminating process. It is typically used to cool down laminates before they are cut, punched, or die-cut.

2. What are the benefits of using a laminating chiller?

Ans - Using a laminating chiller can help reduce the risk of material damage caused by heat, as well as reduce lamination time. It can also help to ensure a more consistent finish on the laminated materials.

3. What types of laminating chillers are available?

Ans - Laminating chillers come in a variety of sizes and types, including air-cooled, water-cooled, and glycol-cooled units.

4. How do I maintain a laminating chiller?

Ans - Regular maintenance is important for keeping a laminating chiller running efficiently. This includes checking coolant levels, inspecting the filters, and cleaning the tanks and coils. It is also important to regularly check the chillers temperature settings to ensure they are set correctly.

Enter Buying Requirement Details

Other Products in 'Industrial Chillers' category

|

DRYCOOL SYSTEMS INDIA (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |