- Home Page

- Company Profile

-

Our Products

- Industrial Chillers

- Blow Moulding Chiller

- Water Cooled Chillers

- Acid Chillers

- Injection Moulding Chiller

- Beverage Chillers (Juice Chillers)

- Chiller for Extrusion Lines

- Chiller For Anodizing

- Anodising Chiller

- Chiller For Anodising

- Co2 Gas Chillers

- Ammonia Milk Chillers

- Bio Gas Chillers

- Bottling Plant Chillers

- Industrial Process Chillers

- Low Temperature Chillers

- Chiller For Electroplating

- Batching Plant Chiller

- Air Chiller

- Air Cooled Scroll Chiller (Single Compressor)

- Chilling Plant Turnkey Project

- Blown Film Plant Chillers

- Industrial Scroll Chillers

- Semi Hermetic Chiller

- Laminating Chillers

- Screw Chillers

- Scroll Water Chiller

- Cooling Tower

- Chilling Plants

- Oil Chillers

- Scroll Chiller

- Glycol Chillers

- Chillers

- Screw Type Water Chiller

- Air Cooled Chillers

- Industrial Chillers

- Extra Links

- Contact Us

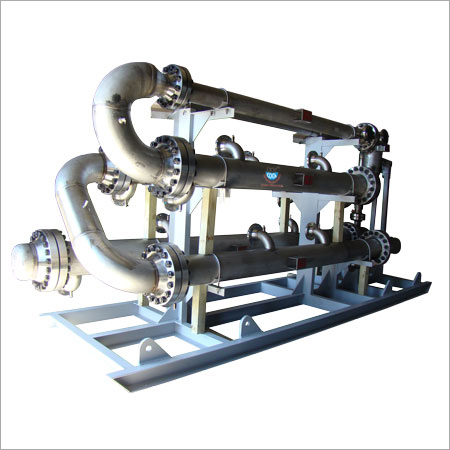

Industrial Process Chillers

155000 INR/Piece

Product Details:

- Color Grey/White

- Material Mild Steel

- Usage Industrial

- Weight 3000 Kilograms (kg)

- Product Type Industrial Process Chillers

- Condition New

- Voltage 415 Volt (v)

- Click to View more

X

Industrial Process Chillers Price And Quantity

- 1 Piece

- 155000 INR/Piece

Industrial Process Chillers Product Specifications

- Industrial Process Chillers

- Industrial

- New

- Mild Steel

- 3000 Kilograms (kg)

- 415 Volt (v)

- Grey/White

Industrial Process Chillers Trade Information

- 1 Week

- Wooden Packing, As per product

- Australia North America South America Eastern Europe Middle East Western Europe Africa Central America Asia

- All India

- ISO 9001:2015

Product Description

Operated using a vapor-compression or absorption refrigerant cycle to cool down a liquid for heat transfer, these Industrial Chillers Manufacturers are available in three major models, air cooled, water cooled and evaporative condensed. Integrated with a highly efficient and noise free heat exchanger, these chillers offer cooling very quickly. Come in compact designs, these equipments are incorporated with high- quality compressors. It works in basic cooling cycle in which the liquid refrigerant changes its phase to gas within an evaporator by absorbing heat from the water to be cooled. The resultant refrigerant gas is then compressed at a higher pressure, transforming backed into a liquid that goes back to the evaporator section.

Features of Industrial Chillers Manufacturers :

- Fully automatic compact Air/water cooled skid mounted unit

- Wide range of capacity from 1 TR to 120 TR with temperature of water/Brine from (+) 20 C degree to(-) 5 C degree

- Main parts are designed and manufactured by DRYCOOL in its plant

- Main critical components of the unit i.e. expansion valve, l.p/h.r switch, dryer of international standard

- Control panel with PLC forauto operation.(optional)

- High quality product due to stage wise inspection & testing before dispatch

- Twelve months guarantee & backed by most efficient customer support

- Innovative design

- Very low input KW/TR

- CFC free refrigerants

- Robust in construction

- Developed with state of art technology

- Liquid injection for enhanced compressor life

- MCS Microprocessor/PLC based/electromechanical

- Heat exchanger design as per TElvlA/ASME/SEC VIII, DM, 2001

The various operating voltages of Industrial Central Chillers are :

- 380 / 400 volt ac / 50 hz

- 460 volt ac / 50 hz

- 380 volt ac / 60 hz

- 460 volt ac / 60 hz

Design data :

- Connected power 415v ac +/- 10 per / 50hz / 3 phase + neutral

- Design condensing temperature (+) 55 degree c.

- Design evaporating temperature (+) 5 degree c.

FAQ

1. What exactly is a process chiller for industry?

Ans - A device used in industrial applications to cool process fluids or machinery is known as an industrial process chiller. To remove heat from the operation, it operates by passing a coolant - typically water - through a heat exchanger.

2. What advantages do industrial process chillers offer?

Ans - Reduced downtime and increased process efficiency are the main advantages of using an industrial process chiller. A well maintained chiller can assist lower energy expenses and lessen the need for expensive equipment replacement or repairs.

3. What varieties of chillers are available?

Ans - There are several distinct kinds of chillers, including evaporative, air-cooled, and water-cooled chillers. When choosing a kind, it's crucial to take the application and environmental factors into account because each type has advantages and disadvantages of its own.

4. What parts of an industrial process chiller are typical?

Ans - Compressor, condenser, expansion valve, evaporator, and reservoir are among the typical parts of an industrial process chiller. The expansion valve and evaporator are used to lower the pressure and further chill the refrigerant after it has been compressed and cooled by the compressor and condenser. The cooled refrigerant is kept in the reservoir until it is required.

5. What safety and maintenance measures must be followed while utilising an industrial process chiller?

Ans - It's crucial to inspect an industrial process chiller before each use to look for any wear or damage and to confirm that it's in good functioning order. When working with the chiller, it's crucial to take all necessary safety precautions, like donning protective gear. The chiller must have routine maintenance in order to function effectively and securely.

Enter Buying Requirement Details

Other Products in 'Industrial Chillers' category

|

DRYCOOL SYSTEMS INDIA (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |